Right-Angled straight Gear Reducer - L Shape

Products

Right-Ang led Straight Gear Reducer (L Shape)

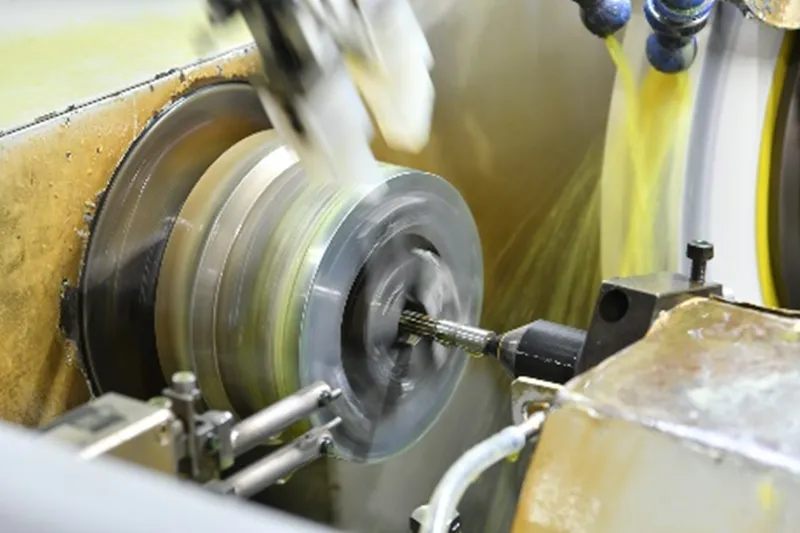

Right-Angled Straight Gear Reducer (L Shape) This right-angled straight gear reducer features a planetary gear system with spur gears and an integrated bevel gear stage to redirect output torque 90 degrees from the input. It offers compact installation for space-limited applications while maintaining high torque density. The straight-cut gears are hardened to HRC58–62 for wear resistance, and the ductile iron housing ensures mechanical durability. Available in single- or multi-stage configurations with a ratio range of 3 to 250, it delivers efficiency of ≥97% and a return clearance of ≤25 arc minutes, making it suitable for right-angle automation axes and robotic joints.

We Are Ready for Any Occasion

Features

Right-Angled Straight Gear reducer

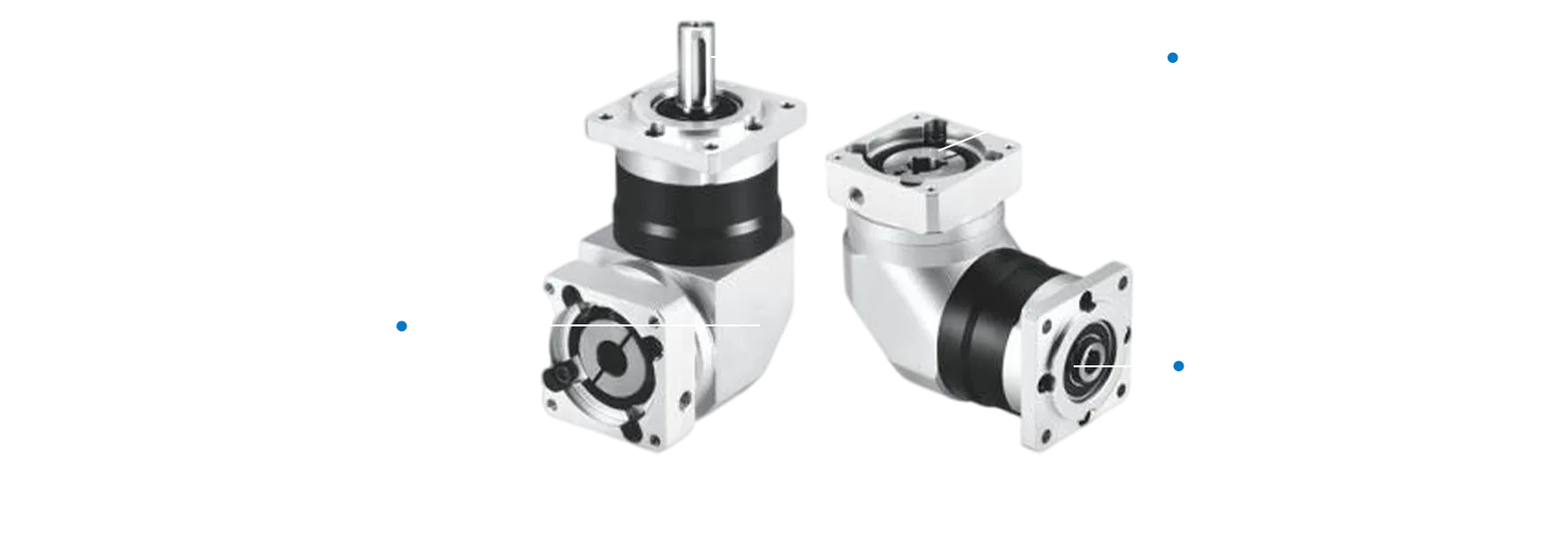

01.VGZE – Shaft Output, Round Flange

Features:

The reducer features an integrated structure combining the output flange and gear ring. Both the output shaftand planet carrier adopt a dual-support cage design, along with a wide-span bearing layout that provides exceptional radial load capacity and

The right-angle housing is equipped with double-row angular contact bearings on both ends, locked in place with a locknut, enhancing the stability of the bevel gear system.

This series delivers superior performance across all key parameters, capable of withstanding high radial loads and moderate axial loads, making it suitable for high-load, high-precision applications involving frequent start-stop motion and changing load conditions.

02.VGZEK – Hollow Shaft Output, Round Flange

Features:

The reducer features an integrated structural design for the output flange and gear ring. Both the hollow output shaft and planet carrier adopt a

The right-angle housing incorporates double-row angular contact bearings on both ends, secured by locknuts to enhance the stability of the bevel gear assembly.

This series offers outstanding performance across all critical parameters, capable of withstanding high radial loads and moderate axial loads, making it ideal for high-strength, high-precision applications with frequent start-stop operations and varying load conditions.

03.VGZF – Shaft Output, Square Flange

Features:

The reducer features a modular separation design for the output flange and gear ring. Both the output shaft and planet carrier adopt a single-support structure with a square output flange.

The right-angle housing is equipped with double-row angular contact bearings on both ends, secured by locknuts, which enhances the stability of the bevel gear system.

This series delivers well-balanced performance across all key parameters, capable of withstanding moderate radial and axial loads, making it suitable for applications with medium to low precision requirements.

04.VGZFK – Hollow Shaft Output, Square Flange

Features:

The reducer features a modular separation design for the output flange and gear ring. Both the hollow output shaft and planet carrier adopt a single-support structure, with a square output flange.

The right-angle housing is fitted with double-row angular contact bearings on both ends, secured with locknuts, enhancing the stability of the bevel gear mechanism.

This series provides well-balanced performance, capable of withstanding moderate radial and axial loads, suitable for applications with medium to low precision requirements.

05.VGZF+ - Longer Shaft Output, Square Flange

Features:

The reducer features a modular separation design for the output flange and gear ring. The extended output shaft and planet carrier adopt a single-support structure.

The output end is supported by two angular contact bearings, locked in place with a nut on both the shaft and output flange to eliminate axial clearance.

The right-angle housing is equipped with double-row angular contact bearings on both ends, improving bevel gear stability.

It offers strong overall performance, capable of handling higher radial and axial loads, making it suitable for medium to low precision applications.

06.VGZF+K - Extended Hollow Shaft Output, Square Flange

Features:

This model features a modular separation design for the output flange and gear ring. The extended hollow shaft and planet carrier adopt a single-support structure.

At the output, two angular contact bearings are locked with a nut onto the shaft and flange to eliminate axial play.

The right-angle housing uses double-row angular contact bearings on both sides, secured by locknuts, to enhance bevel gear stability.

It offers robust performance, suitable for higher radial and axial loads in medium to low precision applications.

07.VGZX42 - Square Body, Shaft Output, Square Flange

Features:

The reducer adopts a modular separation design for the output flange and gear ring. The output shaft and planet carrier use a single-support structure, with a square housing and square output flange.

Double-row angular contact bearings are installed on both sides of the right-angle housing and locked in place to improve bevel gear stability.

The unit supports moderate radial and axial loads, ideal for medium to low precision applications.

08.VGZX 142 - Square Body, Shaft Output, Square Flange

Features:

This model also adopts a modular separation design for the output flange and gear ring. The output shaft and planet carrier utilize a single-support structure, with both the housing and output flange being square.

Double-row angular contact bearingsare installed on both ends of the right-angle housing and secured with locknuts, enhancing bevel gear reliability.

It supports moderate radial and axial loads, suitable for medium to low precision use cases.

09.VGZXK 142 - Square Body, Hollow Shaft Output, Square Flange

Features:

The reducer features a modular separation design for the output flange and gear ring. The hollow output shaft and planet carrier use a single-support structure, with a square housing and square output flange.

Double-row angular contact bearings on both ends of the right-angle housing, locked by nuts, provide stability to the bevel gear system.

It performs reliably under moderate radial and axial loads, suitable for medium to low precision applications.

10.VGZH - Hollow Shaft Bearing Output, Round Flange

Features:

The reducer features an integrated structural design combining the output flange and gear ring. The output end is supported by two tapered roller bearings, locked with a nut to the shaft and housing, eliminating axial clearance and improving torsional rigidity, with superior radial and axial load capacity.

Double-row angular contact bearings are mounted on both sides of the right-angle housing for enhanced bevel gear stability.

This model is suitable for medium to low precision applications requiring extremely high radial and substantial axial load support.

Customized Solutions for Right-Angled Straight Gear Reducer (L shape)

Custom planetary reducers are designed to meet the unique demands of specialized industrial applications where standard gearboxes may not be sufficient. These demands may include specific working conditions, gear ratio requirements, space constraints, or additional functional needs. Our customization process follows the steps below:

- Requirement Analysis & Consultation

- Solution Design

- Technical Evaluation

- Prototype Manufacturing

- Performance Testing & Validation

- Design Optimization (if needed)

- Customer Approval

- Mass Production

- Delivery & After-Sales Support

Frequently Asked Questions

What are the reasons why a drive motor is not loaded?

What drying methods are there for gear motors?

In which steps is a gear motor installed?

How is the reduction gear heat treated?

What is the maximum transmission ratio of a planetary gearbox?