Is precision machining a sunset industry? Many people think so. People think that precision machining is not comparable to IT, medicine, electronics and other industries, but precision machining is by no means a backward industry. Until now, many parts and components of tools and items we use and rely on in our daily lives are produced by precision machining. In fact, precision machining technology is still developing further, and many visionary companies are still investing a lot of money to improve the efficiency of precision machining and create hardware and software to support the latest technological developments. But what is precision machining? Here, we will take a closer look at what precision machining is and how it can be used to support the advancement of modern manufacturing.

What is precision machining?

Precision machining can be defined as the use of tools, procedures, engineering talents or equipment to the maximum capabilities to achieve the limits of production and materials science, and to perform these operations under the strictest tolerances of these manufacturing. Precision machining is a mechanical processing manufacturing process that plays an irreplaceable role in the production and design of machines, parts, tools and other hardware that are essential in modern manufacturing, and can ensure that the equipment required by modern society operates under extremely strict specifications. Precision machined parts are used to make up many large and small objects and their components used in our daily lives. If an object is made up of many small parts, those small parts often need to be made by precision machining to ensure they fit together precisely and work properly. Clearly, precision machining has evolved over time, and advances in all the related technologies have helped push the limits of what defines precision machining and consistently improve performance. The true art of precision machining comes from the combination of computer-controlled design and human engineering to create unique features and highly controlled outputs and functions, driven by advances in fluid dynamics, chemical control, mechanics, extreme climates, and durability required by modern hardware. Precision machining is especially important for making tools and parts in a precise, stable, and repeatable manner with accuracy, consistency, and durability.

What is precision machining used for?

Precision machining is a subtractive process used for processes that require material to be removed from raw materials to create a finished product. Precision machining can be used to make a wide variety of products, items, and parts for any number of different objects and materials. These parts are often required to have very precise dimensions, which means there is not much room for error in the production of the part. Repeatability and well-controlled tolerances are the hallmarks of precision machining.

The most common use of precision machining is to produce components, parts, and finished products that are designed to maintain very tight tolerances and high durability. For example, parts that work together as part of a machine may need to be aligned to within very small dimensions of 0.01 mm to 0.05 mm at all times. Precision machining helps ensure that these parts are not only manufactured accurately, but can be produced repeatedly with this level of accuracy.

Another common application for precision machining may be when a tool or component needs to be repaired or restored. After a period of use, the tool or part of an object may need to be machined, notched, or welded to restore it to its original condition. This can also be accomplished through precision machining.

How does precision machining work?

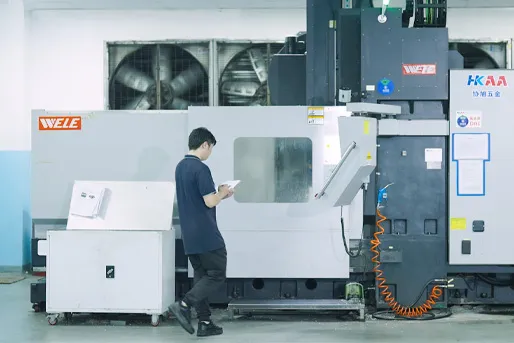

Precision machining is a subtractive process in which operators use custom software, tools, and fixtures to place metals, plastics, ceramics, or composite materials into a processing device and then produce the fine features required. Precision machining usually follows instructions given by computer-aided design (CAD) and computer-aided manufacturing (CAM) programs. These programs and instructions ensure the tolerances of precision parts. While most designs are ultimately computer-aided designs, many designs begin with hand-drawn sketches in the initial stages.

What equipment and materials are used for precision machining?

Precision machining can use a variety of materials, including metals, plastics, ceramics, composites, and more. To perform precise machining, a variety of equipment can be used to achieve the desired size and shape. These tools vary depending on the raw material. Common tools include milling machines, lathes, electrical discharge machines (aka EDM), saws, and grinders. The most commonly used manufacturing equipment is computer-controlled CNC machining centers and CNC lathes, which are designed to remove excess material and create fine components and parts.