CNC Milling

China Top CNC Milling Supplier & Manufacturer – Junying offers worldwide clients affordable, rapid, high precision custom CNC Milling Services, variety of materials available to meet the needs of different industries!

What is CNC milling?

CNC milling is a process that uses computer numerical control (CNC) technology to cut and process workpieces through rotating tools. According to computer instructions, the CNC milling machine controls the tool to move along a predetermined path, removes excess material from the workpiece, and forms the desired shape and size.

Why choose CNC milling?

High precision: CNC milling can achieve extremely high processing accuracy and meet the stringent requirements for part size and shape.

High efficiency: With a high degree of automation, the processing efficiency is much higher than traditional manual processing.

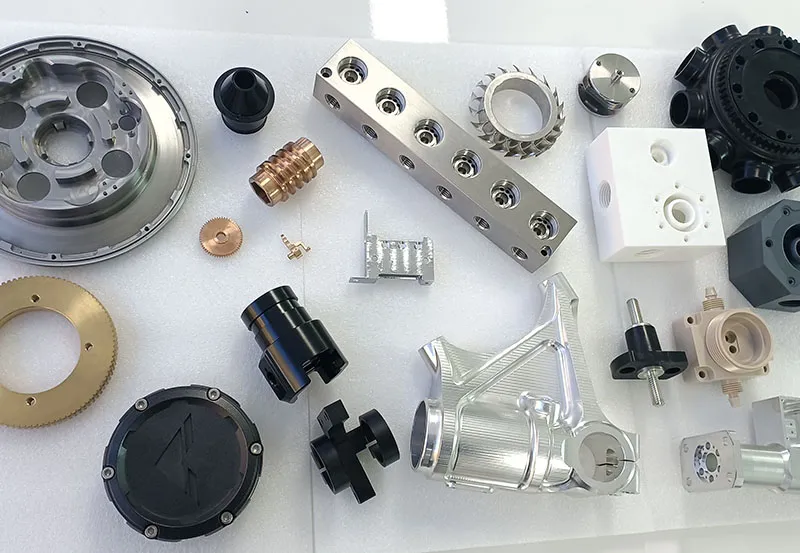

Complex shapes: Various parts with complex shapes can be processed, including curved surfaces, inclined surfaces, etc.

Mass production: Suitable for mass production to ensure product consistency.

Wide range of materials: Can process a variety of materials such as metals and plastics.

CNC milling material options

CNC milling can process a wide range of materials, the most common ones are:

Metal materials: aluminum alloy, stainless steel, copper, titanium alloy, etc.

Engineering plastics: ABS, PC, POM, PEEK etc.

Composite materials: carbon fiber, glass fiber, etc.

Different types of CNC milling machines

Based on the number and configuration of axes, CNC milling machines can be divided into the following categories:

Three-axis milling machine: Three linear axes X, Y, and Z, suitable for processing flat parts.

Four-axis milling machine: Add a rotary axis on the basis of three axes, which can process inclined surfaces and partial curved surfaces.

Five-axis milling machine: With two rotary axes, it has the strongest processing capacity and can process various complex curved surfaces.

Why choose HKAA Milling Service?

Rich experience

We have many years of CNC milling experience and can provide customers with professional solutions.

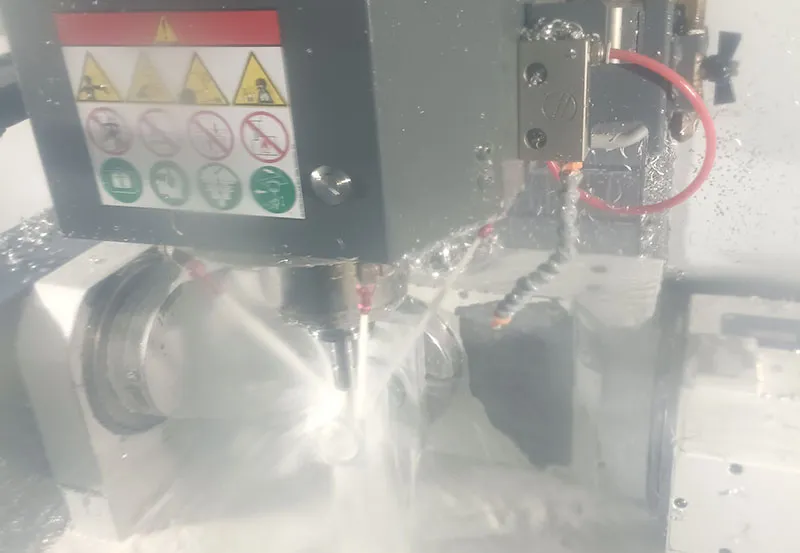

Advanced equipment

We have advanced CNC milling machines and measuring equipment.

Professional team

Our team consists of experienced engineers and technicians.

High-quality service

We provide one-stop service from design, processing to after-sales.

Surface treatment

According to customer needs, we can provide a variety of surface treatment services, such as:

Anodizing: Improve the corrosion resistance, hardness and aesthetics of aluminum alloys.

Electroplating: Plate a layer of metal on the surface of parts to improve corrosion resistance and decorativeness.

Sandblasting: Grind the surface, increase surface roughness and increase adhesion.

Polishing: Make the surface smooth and improve gloss.