CNC Prototype

What is CNC Prototype Service?

CNC Prototype Service refers to the use of computer numerical control (CNC) machine tools to quickly produce prototypes that are highly consistent with the final product size, shape, and function based on the 3D model or drawing provided by the customer. This service plays an important role in the early stages of product development and can help designers and engineers verify product design, evaluate product performance, and conduct functional testing.

Advantages of CNC Prototype Service

Rapid prototyping: CNC machining can quickly transform designs into physical objects and shorten product development cycles.

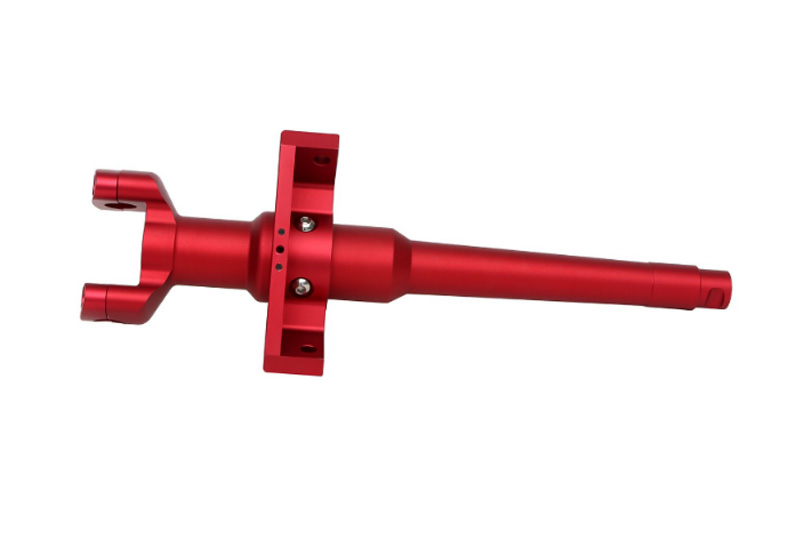

High precision: CNC machining has high precision and can produce prototypes with precise dimensions and smooth surfaces.

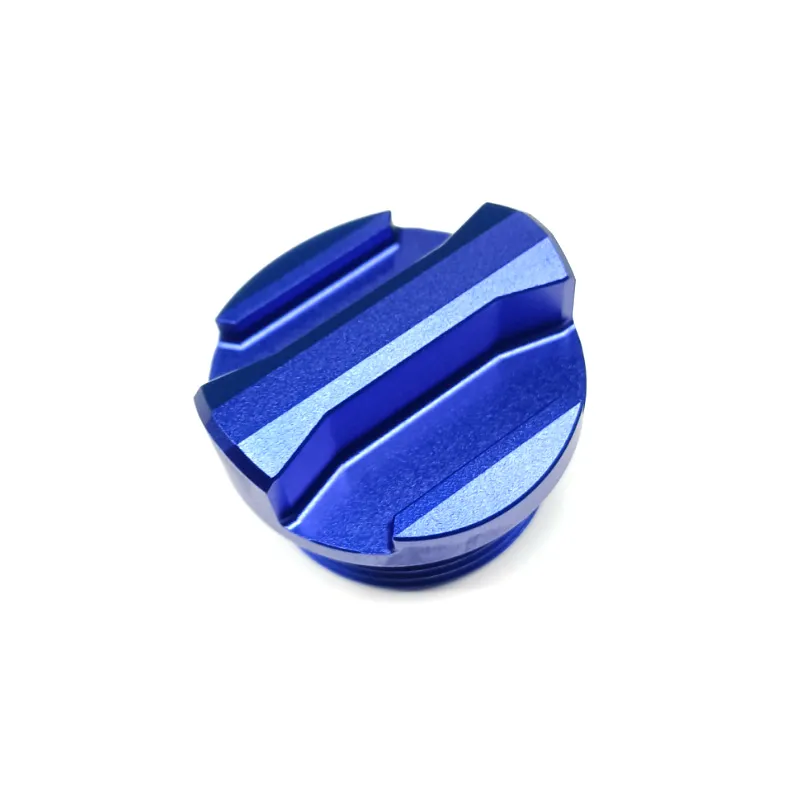

Material diversity: CNC machining can process a variety of materials, including metals, plastics, composite materials, etc., to meet the needs of different products.

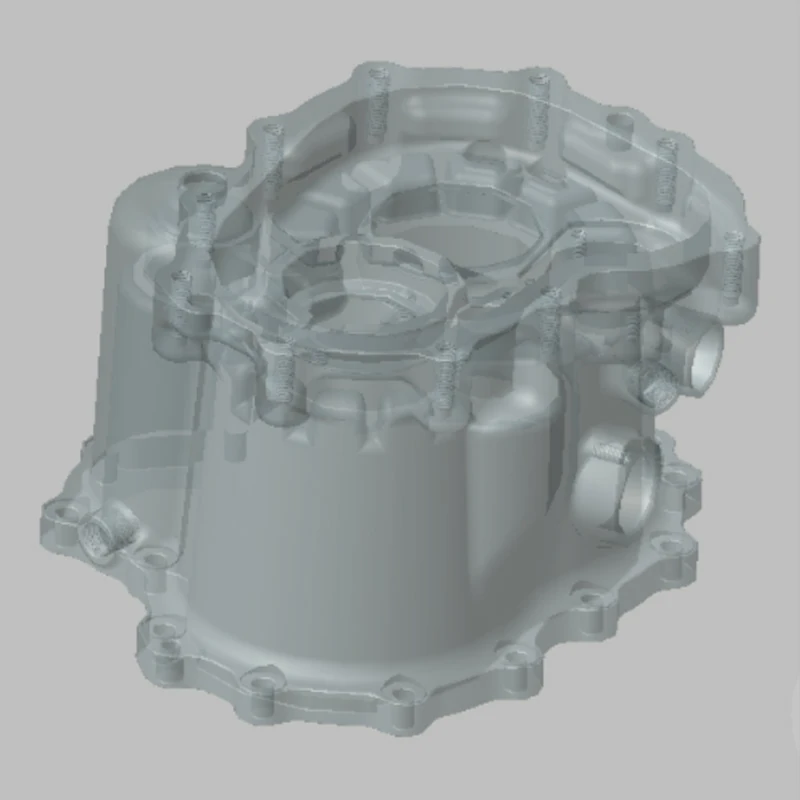

Complex structure: CNC machining can process parts with complex shapes to meet personalized customization needs.

Repeatability: CNC machining can mass-produce the same prototypes, which is convenient for comparative testing.

Cost-effectiveness: Compared with traditional manual production, CNC machining is cheaper and more efficient.

Application of CNC Prototype Service

Product Design Verification: In the early stage of product design, by making prototype parts, it is possible to verify whether the appearance, size, and function of the product meet the design requirements.

Functional Testing: Through prototype parts, product performance tests can be carried out, such as strength testing, wear resistance testing, etc.

Mold Manufacturing: CNC processing can quickly manufacture molds for small batch production or trial production.

Concept Verification: Transform ideas into physical objects to verify the feasibility of products.

Market Research: Collect user feedback and optimize product design by displaying prototype parts.

Our CNC Prototype Service

Material Selection: Provide a variety of material options to meet the needs of different products.

Precision Control: Use high-precision CNC equipment to ensure the dimensional accuracy of prototype parts.

Surface Treatment: Provide a variety of surface treatment processes, such as sandblasting, electroplating, oxidation, etc., to improve the appearance and performance of prototype parts.

Fast Delivery: Shorten the delivery cycle by optimizing the production process.

Confidentiality: Strictly protect the customer’s design information and ensure the security of intellectual property rights.

CNC Prototype Service FAQ

What is the difference between CNC Prototype Service and 3D Printing?

What information do you need to provide for CNC prototyping?

How long is the CNC prototyping cycle?

How to calculate the cost of CNC prototyping?