Wire EDM

What is Wire Cutting?

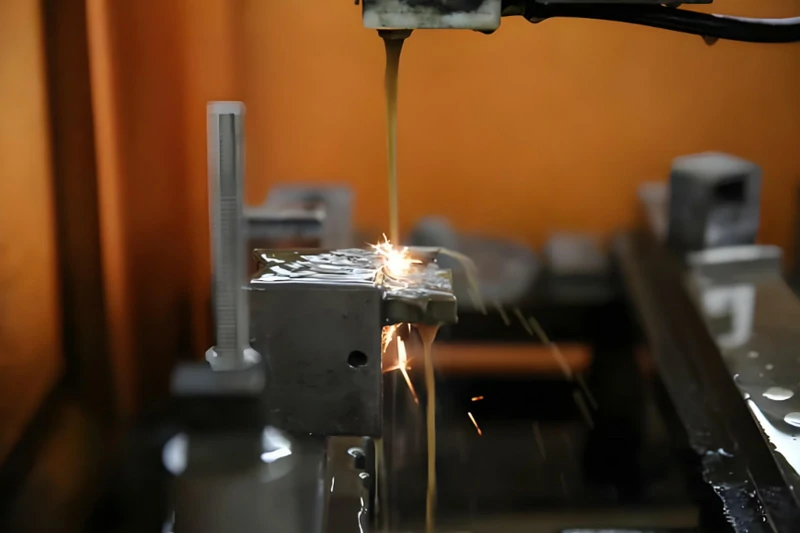

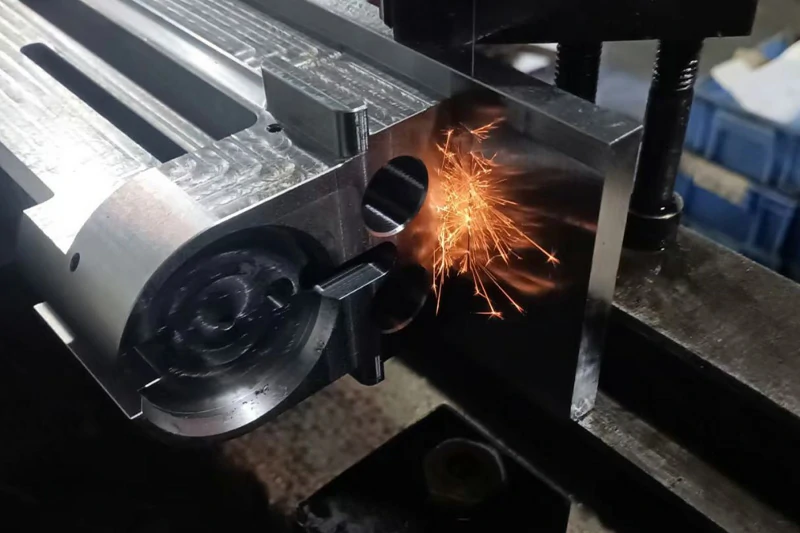

Wire cutting, also known as wire cutting discharge machining, is an advanced technology that uses the principle of electric sparks to cut conductive materials. It uses a continuously moving thin metal wire as an electrode to generate high-frequency pulse discharge between the workpiece and the electrode, so that the workpiece is locally melted and vaporized at the discharge point to achieve the purpose of cutting.

Application of Wire Cutting

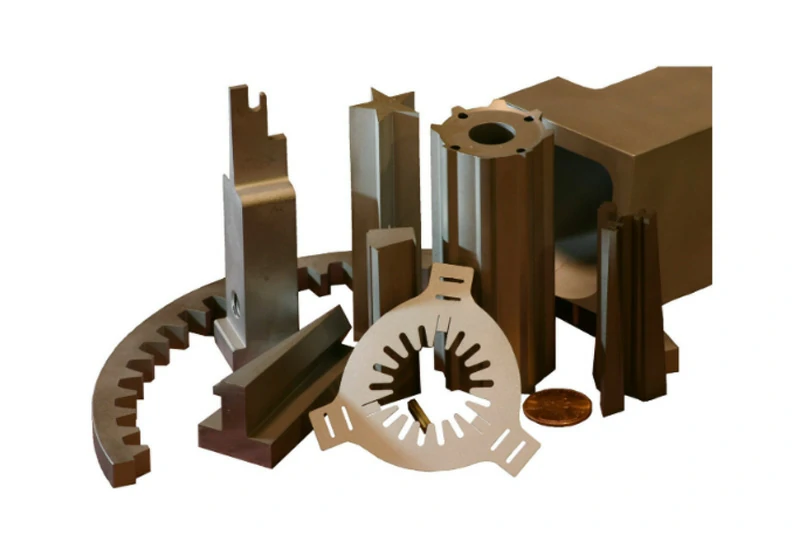

Wire cutting technology is widely used in various fields, such as:

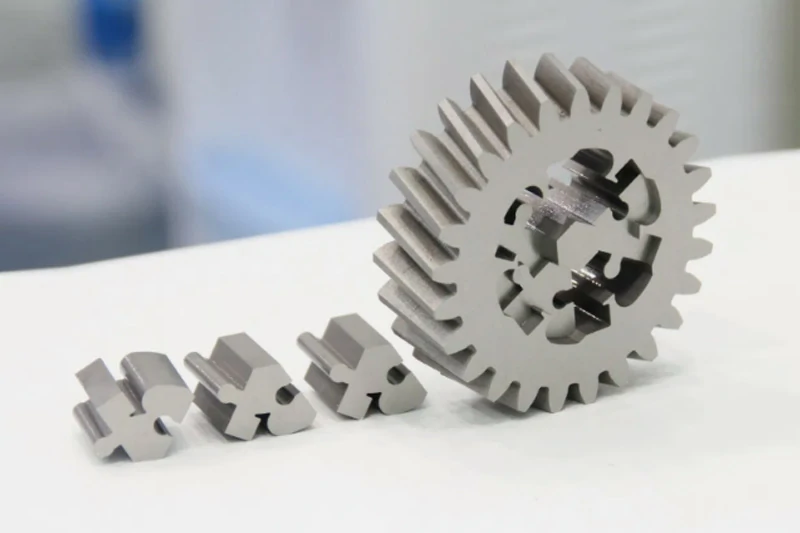

Mold manufacturing: Manufacturing molds of various complex shapes, such as stamping molds, injection molds, etc.

Machinery manufacturing: processing precision parts, tools, measuring tools, etc.

Aerospace: Processing blades and turbine disks of aircraft engines.

Electronics industry: Processing precision electronic components, circuit boards, etc.

Advantages of Wire Cutting

High Precision: Wire cutting has high processing precision and can process complex shapes and small holes.

No Cutting Force: No cutting force is generated and no deformation of the workpiece is caused.

Wide Range of Applicable Materials: Various conductive materials can be processed, including cemented carbide, stainless steel, copper, etc.

Flexible Processing: It can process workpieces of various shapes with strong adaptability.

Why Choose HKAA?

Advanced Equipment

HKAA has advanced wire cutting equipment to ensure processing accuracy and efficiency.

Rich Experience

With many years of experience in wire cutting processing, it can solve various complex processing problems.

Quality Assurance

Strict quality control system to ensure product quality.

Customer Service

Provide professional technical support and perfect after-sales service.

FAQ For Common Precision Processing Problems

Q: What is the minimum line width of wire cutting processing?

Q: What is the surface roughness of wire cutting processing?

Q: What are the requirements for workpiece materials for wire cutting processing?

Q: What is the cost of wire cutting processing?

Materials Compatible With Wire Cutting

Wire cutting can process various conductive materials, including:

Metals: Stainless steel, carbon steel, tool steel, aluminum alloy, copper alloy, etc.

Alloys: Cemented carbide, heat-resistant alloy, etc.