5-axis CNC Machining

DEK offers high precision, fast turnaround 5 axis CNC machining services. With advanced 5-axis CNC machines and a wide selection of materials, DEK is able to provide 5-axis machined parts with complex geometries to tight tolerances of +/-0.005mm.

What is five-axis CNC machining?

Five-axis CNC machining is an advanced CNC machining technology that has more powerful machining capabilities than traditional three-axis or four-axis machining. In addition to the traditional three linear axes of X, Y, and Z, the five-axis CNC machine tool also adds two rotary axes (usually A and B or C axes), allowing the tool to approach the workpiece from almost any angle. This enables five-axis machining to produce more complex and precise parts, and achieve multi-faceted machining in one clamping, greatly improving machining efficiency and precision.

Advantages of five-axis CNC machining

Strong ability to process complex parts: Five-axis machining can process parts with various complex curved surfaces, inclined surfaces, conical surfaces, etc., to meet the needs of aerospace, automotive, mold and other industries for high-precision parts.

High machining efficiency: Multi-faceted machining is completed in one clamping, which reduces the number of workpiece clamping and tool changes, greatly improving machining efficiency.

High machining accuracy: The accuracy of five-axis machining is higher than that of traditional machining, and it can process parts with more precise dimensions and better surface quality.

Small machining allowance: Since the tool can approach the workpiece from multiple angles, the machining allowance can be smaller, reducing material waste.

High degree of automation: Five-axis machining can achieve a high degree of automation, reduce manual intervention, and improve production efficiency.

Application of five-axis CNC machining

Five-axis CNC machining has a wide range of applications in many fields, such as:

Aerospace: Processing complex parts such as blades and fuselage skins of aircraft engines.

Automobile manufacturing: Processing parts such as automobile engine cylinder heads, crankshafts, and gearbox housings.

Mold manufacturing: Processing molds of various complex shapes, such as injection molds, die-casting molds, etc.

Medical devices: Processing precision medical devices such as artificial joints and implants.

Electronic products: Processing electronic product shells such as mobile phone shells and computer cases.

Our five-axis machining services

Customized processing of complex parts: According to the drawings or samples provided by the customer, we provide one-stop services from design, programming to processing.

Material diversification: Supports processing of various metal materials, engineering plastics, etc.

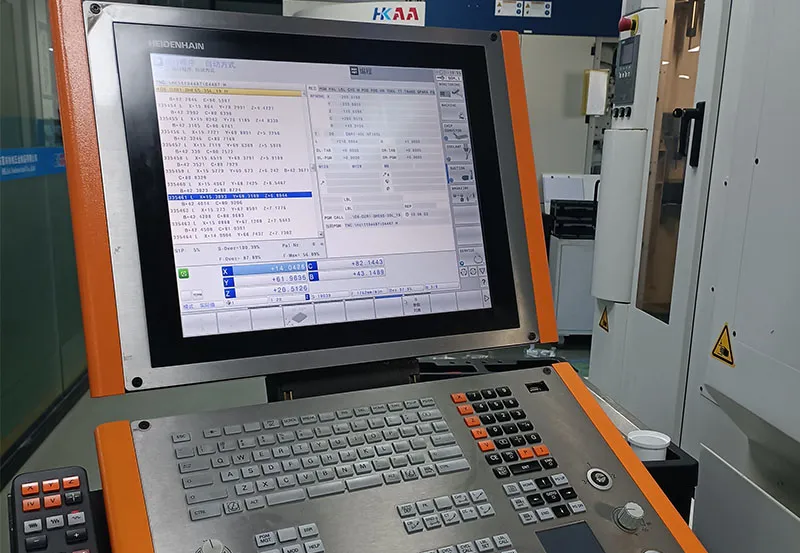

High-precision processing: Use advanced five-axis CNC machine tools and measuring equipment to ensure processing accuracy.

Fast delivery: Shorten the delivery cycle by optimizing the production process.

After-sales service: Provide perfect after-sales service to protect the rights and interests of customers.