CNC Turning

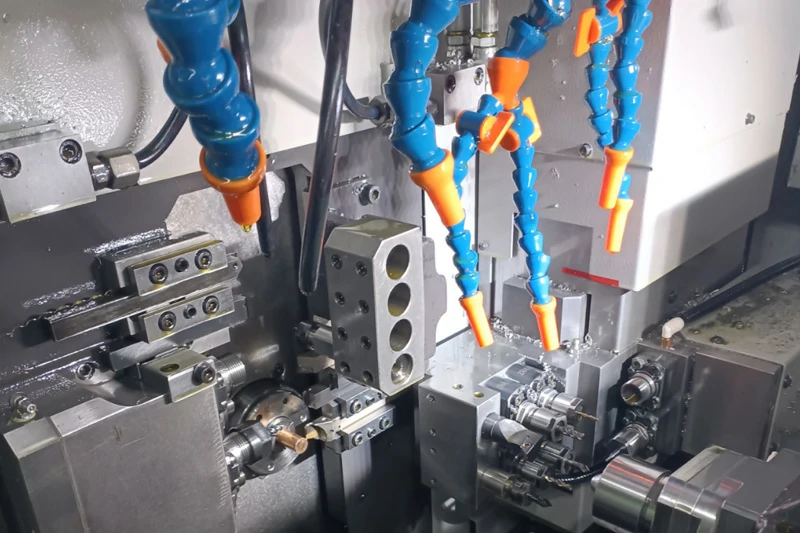

One-stop machine shop for CNC turning services using CNC lathes with live tooling for custom parts

What is CNC turning?

CNC turning is a processing method that uses computer numerical control (CNC) technology to process cylindrical or rotationally symmetrical parts of various shapes by rotating the workpiece and cutting with a tool. CNC turning machines can efficiently process high-precision, high-surface quality parts by precisely controlling the motion trajectory of the tool.

Why choose CNC turning

High precision: CNC turning can achieve extremely high dimensional accuracy and tolerance control to meet the processing needs of precision parts.

High efficiency: CNC turning has a high degree of automation and its processing efficiency is much higher than traditional turning.

Complex shapes: CNC turning can process various complex cylindrical, conical, threaded and other parts.

Mass production: CNC turning is suitable for mass production to ensure product consistency.

Wide range of materials: CNC turning can process a variety of metal materials, such as stainless steel, aluminum alloy, copper, etc.

CNC milling material options

Common materials for CNC turning include:

Metal materials: stainless steel, aluminum alloy, copper, titanium alloy, carbon steel, etc.

Engineering plastics: POM, PEEK, PC, etc.

Different types of CNC lathes

Horizontal lathe: The spindle is placed horizontally, suitable for processing longer workpieces.

Vertical lathe: The spindle is placed vertically, suitable for processing shorter workpieces.

Multi-axis lathe: In addition to the spindle, it also has multiple auxiliary axes to complete more complex processing.

Turret lathe: The tool is installed on the turret, with fast tool change and high efficiency.

Our turning capabilities

Complex part processing: We are able to process parts of various complex shapes, including tapers, threads, grooves, etc.

High-precision processing: We have high-precision CNC lathes that can meet customers’ demanding requirements for part accuracy.

Small batch customization: We provide small batch customization services to meet customers’ personalized needs.

Material diversification: We can process a variety of metal and non-metal materials.

Surface treatment: We provide a variety of surface treatment processes, such as polishing, electroplating, heat treatment, etc., to improve the corrosion resistance and aesthetics of parts.

Process Features

Flexible Programming

CNC turning is controlled by computer programming, which is flexible and easy to modify.

High degree of automation

CNC turning has a high degree of automation, which reduces manual intervention and improves production efficiency.

Stable Processing Quality

CNC turning has stable processing quality and good product consistency.

Why choose our turning service?

Rich experience: We have many years of experience in CNC turning and can provide customers with professional solutions.

Advanced Equipment: We are equipped with advanced CNC lathes and measuring equipment.

Strict Quality Control: We have established a complete quality management system to ensure product quality.

Professional Team: We have an experienced technical team that can provide customers with a full range of services.