CNC Turning & Milling

What is CNC turning and milling compound processing?

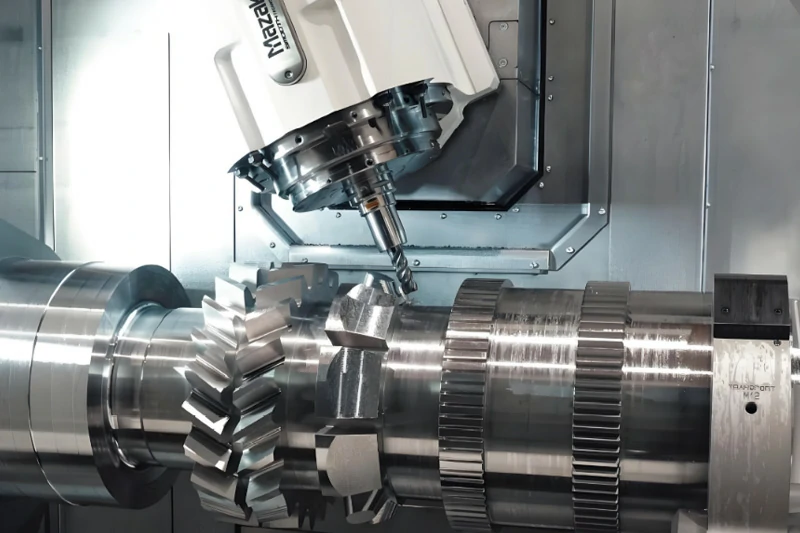

CNC turning and milling compound processing is a modern CNC processing technology that combines two traditional processing methods, turning and milling. Through one machine tool, turning and milling processes are completed at the same time, which greatly improves the processing efficiency and the accuracy of parts.

Advantages of CNC turning and milling compound processing

High efficiency: Multiple processing can be completed in one clamping, which reduces the time of workpiece clamping and machine tool conversion, and improves production efficiency.

High precision: Using CNC technology, high-precision and high-complexity parts processing can be achieved.

High flexibility: It can process parts of various complex shapes with strong adaptability.

High degree of automation: Through programming, automatic processing can be achieved, reducing manual intervention and reducing production costs.

Material saving: Reduce the workpiece allowance and improve material utilization.

Principle of CNC turning and milling compound processing

CNC turning and milling compound processing machine tools are usually equipped with B-axis and C-axis. The B-axis can tilt the spindle and the C-axis can rotate the spindle, so that various angles of processing can be completed in one clamping. Through the computer numerical control system, the movement of the machine tool is controlled to achieve the composite processing of turning and milling.

Application fields of CNC turning and milling composite processing

Automotive industry: Processing automobile engine parts, gearbox parts, steering system parts, etc.

Aerospace: Processing aircraft engine parts, fuselage structural parts, etc.

Mold manufacturing: Processing mold cavities, mold inserts, etc.

Medical devices: Processing precision parts of medical devices.

Electronic products: Processing precision parts of electronic products.