High Precision Machining

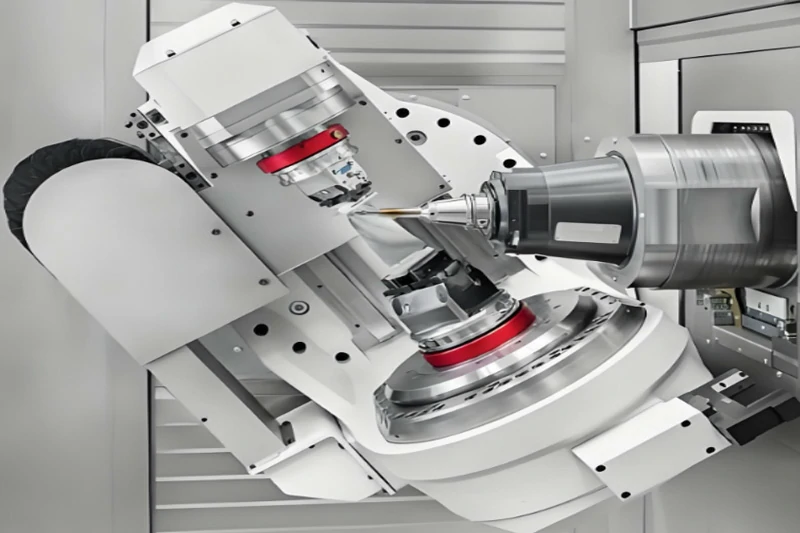

CNC 5 axis machining

HKAA owns a group of world-leading precision five-axis machining centers, including well-known brands such as GROB, GF, and MAZAK. The introduction of these equipment has given HKAA strong capabilities in high-precision and complex parts processing.

HKAA’s machining centers can process parts to a very high level of precision, meeting the high requirements for part accuracy in aerospace, automotive, medical and other fields.

Advantages of five-axis linkage machining center

Compared with traditional machine tools, five-axis linkage machining centers have the following significant advantages:

High precision: Complex curved surfaces and free-form surfaces can be processed with an accuracy of ±0.0001 inches.

High efficiency: Multi-faceted processing can be completed in one clamping, which reduces the number of clamping times of the workpiece and improves processing efficiency.

High flexibility: Can process parts of various shapes and has strong adaptability.

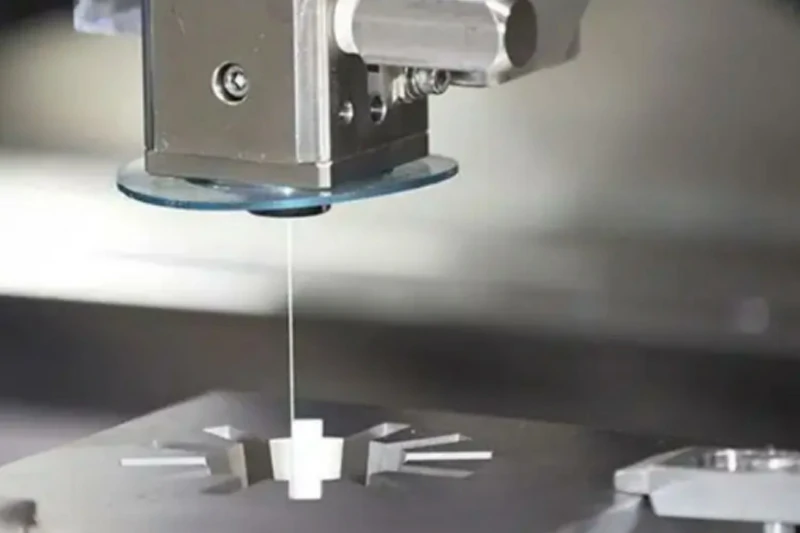

EDM CNC machining

Electrical discharge machining (EDM) is a non-traditional machining method that uses the high temperature generated by electric sparks between the tool electrode and the workpiece to erode the workpiece material. The uniqueness of this method is that it can achieve extremely high machining accuracy, even reaching the micron level and even the sub-micron level, far exceeding traditional machining methods.

Grinding

HKAA’s grinding process uses two core processes of surface grinding and cylindrical grinding to give the workpiece a surface finish and dimensional accuracy that far exceeds conventional.

High-precision testing equipment

The two coordinate measuring machines owned by HKAA, especially the Zeiss coordinate measuring machine, provide customers with high-precision and multi-functional measuring services. Through GD&T testing, the quality and reliability of products can be ensured and customers’ stringent requirements for product accuracy can be met.